Sanmar’s Bogacay XXXVIII, the world’s first Advanced Variable Drive (AVD) tugboat, which has been providing towage services at Izmit Bay since late February, has been performing superbly according to a recent statement from Sanmar.

In a recent press release about the vessel’s performance, Sanmar noted the tug “has performed admirably” alongside her diesel mechanical sisters in the Izmit Bay fleet. The company recalled that the vessel was introduced into Sanmar’s fleet on 25 February, following its commissioning ceremony on 11 January at Sanmar’s yard in Altinova.

Sanmar quoted the company’s Vice President Ali Gürün commenting on the new tug: “Innovation, respect for the environment, quality, form, function, aesthetics and art – are all essential parts of this new tugboat and these qualities also describe Sanmar very well.”

A primary advantage of the CAT AVD system is its continuously variable transmission, which can modulate propeller speed down to 0 rpm like a slipping clutch. It can also spin the propeller up faster than would be possible if the engine was directly coupled to the drive, allowing the engines to operate in their peak efficiency zone instead of operating along the propeller demand curve at higher specific fuel oil consumption, thus resulting in significant fuel savings. With an FP propeller pitched for bollard condition at 0 knots, this feature enables full power to be taken from the engine when free running, much like a CP or DEP system.

Optimal engine efficiency

In the words of Nathan Kelly, Caterpillar Marine Product Definition Engineer: “This (AVD system) allows propeller speed independent of engine speed so optimal engine efficiency can be achieved leading to fuel savings of fifteen to twenty percent. Basically, all the benefits of a variable speed Diesel Electric Propulsion (DEP) system at a fraction of the cost and size.”

Other advantages include improved response and acceleration as well as lower overall maintenance costs due to significantly reduced operating hours on the main engines.

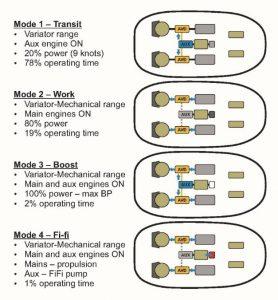

With this system the engines are smaller than they would normally be in a tug of this power (3512 vs. 3516 engines). The additional power to achieve maximum bollard pull comes from the C32 engine that also drives the Fi-Fi pump. The diagram illustrates the machinery configuration and power flow scenarios for the four operating modes.

Vessel specs

The vessel has been outfitted to Sanmar’s usual very high standards for a crew of six people. The main deckhouse contains the galley, mess, two officer cabins, and a common WC. The lower deck contains two double berth cabins, a laundry, galley stores, and a common WC space. The wheelhouse provides all round maximum visibility and exceptional visibility to the bow and side fendering. The engine room features a small, sound resistant switchboard room.

On trials, Boğaçay XXXVIII achieved 70.35 tonnes bollard pull and a free running speed of 13.3 knots.

This first of its kind will now continue to provide valuable data on OPEX savings related to anticipated reductions in fuel consumption and planned maintenance costs compared to her diesel mechanical equivalents, sharing similar operating profiles in the same location. This data will be used by Sanmar and their partners in this project to not only drive marketing of this technology but to assist in scaling this technology across a wider bollard pull range in due time.

Bu haberin/makalenin tamamı ya da bir kısmı kaynak gösterilmeden yayımlanamaz. Kaynak gösterilse dahi aktif link verilerek kullanılabilir. Kaynak göstermeden ve aktif link vermeden yayımlayanlar hakkında yasal işlem başlatılır.